Building my 26’ Norwalk Island Sharpie by

Klaus Sussenbach

Part 2,

the building process:

The

materials list which came with the plans needs to be changed if the boat is

going to be modified in any way. Even with my extensive modifications I used less

plywood than I had expected, some of the left over sheets were later used to

build a stitch and glue dinghy.

For the

sharpie I used the following plywood, all 8x4’ sheets:

1sheet 12mm

okoume marine plywood

27

sheets 9mm -.-

2

sheets 6mm -.-

8

sheets 4mm -.-

8

sheets 12mm hoop pine marine plywood

2

sheets 6mm -.-

1

sheet 3mm -.-

It pays

to order all the plywood at once as there are quantity discount and transport

cost savings. This also applies to the epoxy resin. Most of the other materials

were bought as they were required. I kept looking for boating gear specials at

boat shows etc. and purchased many items which were only required at fit out

time. Leave electronic items until last, it outdates too quickly. This way, by

the time the hull was completed I had accumulated most of the hardware,

spreading this considerable expense over a long period.

I also purchased the mast and booms early in

the process of building the boat and often took to rigging them while waiting

for the epoxy to go hard. Think carefully before drilling holes into these,

some areas are under high stress and some fittings need to wait for

installation until you have the sails to get their exact location.

For the

solid timber a variety, locally available, was used, including teak, jarrah,

kauri pine, western red cedar, douglas fir, and american white ash.

Don’t

worry if you cannot find the required lengths of clear solid timber as these

can easily be scarfed from shorter pieces.

How

much did it all cost?

Rather

than boring you with what the finished boat cost me I calculated the

percentages where the money went. This is for a complete boat, on a trailer, ready to go cruising (just add food

and fuel).

The biggest

item at 24.5% was the 1000’s of miscellaneous things that go into a boat such

as hardware, rigging, ropes, blocks, sheaves, electrical items, plumbing, nuts,

screws, bolts, fittings etc. etc.

Next

with 15% came all the plywood and solid timber used.

Then at

12% came the sails, comprising of the main, mizzen and staysail.

Followed

by 10.5% was the epoxy (I used 100 litres), glass cloth & tape, fillers,

graphite, measuring pumps etc.

The

cost of the home built trailer amounted to 8% of the total.

The mast

and boom extrusions (aluminium) took 7.5 %.

Major

electronics (including autohelm, 27Mhz radio, log, depth sounder and Honda

battery charger) were 6.5%.

Outboard

motor & fuel tanks, 6%.

Safety

gear, 3%.

Paint,

varnish, brushes, rollers etc., 2%.

Boat bunk

cushions and covers, 2%.

Lead

for ballast, 1.5%.

Labour

for welding of stainless and aluminium fittings and parts, 1.5%

That

should give you some idea where the money goes and where you might save some

should you wish to build a less elaborate boat. Please remember that these are rough figures which apply to my

location and may be not comparable elsewhere.

For the

building, a number of homemade items came in very useful, they were:

Circle

guides, I wrote down every small radius on the plans and cut a circle for this

out of scrap 3mm perspex pieces, with a flying cutter. This gizmo may be known

by a different name, it has a shaft to

fit into a drill chuck on which is a 6mm pilot drill bit and an adjustable arm

with a downward facing cutting blade. Make sure the blade is set for disk

cutting rather than for hole cutting. You can use this only on a pedestal drill

with the perspex firmly supported, cut through half of the thickness from each

side to avoid cracking of the perspex and take care! I also cut out many

smaller size disks down to 20mm diameter and ended up with a stack of disks. It

was much easier and quicker to lay a

disk on the appropriate spot on the plywood and draw the required circle

segment than using a compass would have been.

A

straight flat batten, slightly longer than the largest cabin top curve radius,

on one end of which a small hole to hold a nail was drilled. From this hole I

marked the required radius towards the other end of the batten and drilled a

further hole to just fit the tip of a pencil. To use, tap the nail in at the

fulcrum and use the batten as a very long compass to draw the curve section. To

avoid wasting plywood, as this fulcrum often falls outside the sheet, you need

to slip another sheet under it which has a centre line on it. Line this up with

your first sheet and draw the curve section. I did all this on the floor with

weights on the sheets to stop things moving out of alignment.

It pays

to consider carefully how the bulkheads are cut out of the ply sheets and how

to use the off cuts for smaller items, its there were the savings in plywood

sheet numbers come from.

As the

narrow sections across the top and bottom of the bulkheads are trebled, for my

boat I cut some of the bulkheads from sheets butted onto each other while

drawing the shape, giving me a port and starboard half, the butt being the

centre line. It is important to line resulting the halves up carefully when

gluing on the doublers to have a smooth cabin top curve. Experiment a little to

minimise wastage, its easy to rub out a pencil line and mark again.

A

clamping jig for the many scarf joins on the long solid timber pieces. This was

made from 2 lengths of 50x50x3mm (2”x2”x1/8”) angle iron and a piece of flat

bar, 100x5mm (4”x3/16”), all about 1.8m (6’) long. The angle irons were bolted

to each side of the flat bar to form a “+” cross section, the bolts all in the

lower section of the ”+”. This gave two right angles to line up the scarfes for

gluing, it allowed the gluing of two

scarf joins simultaneously. Cover the gluing surfaces with plastic packing tape

to prevent the epoxy sticking there. To use it I clamped the jig into a vice,

placed the timber pieces on the covered section, gluing face up and applied the

epoxy to both surfaces. Always apply a straight epoxy coat first, let it soak

in, reapply more until surface remains wet, then mix in the thickening compound

and apply to both surfaces. Flip the pieces on one end of the jig over so that

the thin edge of the scarf is against the flat bar and clamp them to it. Then

flip one the other pieces over, line up the scarf and carefully clamp down to

the angle iron, making sure it does not move sideways. Repeat for the last

piece, then place clamps across the scarf area and along the jig length to keep

all tucked tight into the corners and lined up straight. Do a dry run for the

first time to get it all worked out without the messy epoxy.

For the

scarfing on the jig above and for other jobs a couple of adjustable stands come

in very handy. I made mine from an old plough disk as a base, welded on a

vertical tube in the centre and had another tube telescoping into this, locked

by a screw knob. The top of the smaller tube had a cross piece welded on where

I fitted a roller. This roller is for using the stand with the bandsaw or table

saw but not needed if you don’t have these machines.

I made

4 sturdy saw horses from hardwood, very useful

to work along the hull later. I also had two stools of half the

sawhorses height, again very useful.

Long boards

are also required, known as “torture boards” in these parts, I had a 900mm (3’)

long one and two 600mm (2’) long ones which had different thickness bases to

bend to the hull curvature. The longer one was more tiring to use but faired

the better in most places. Its important to have comfortable handles on them to

reduce fatigue, you’ll be swinging them for hours on end. I bought the 100mm

wide (4”) sandpaper for them in 50m rolls, one of 80 grade and one 120 grade,

its much cheaper than buying by the metre and it all was used up. The handles

on my boards (mushroom shape) had a groove in their bases to clamp the sanding

paper over a matched bump on the board. I undid two wing nuts, placed the paper

ends under the handle bases and clamped them back on to hold the paper firm.

All

this sanding makes a lot of dust which is not healthy to breathe in. I am a

wearer of glasses and have a beard and this made using disposable dust masks

useless for me. I purchased one of the hood type masks with face shield which

completely cover the head. These have a tube emerging from the back of the hood

which normally connects to a filtered air pump, worn on the belt, to supply

clean air to the wearer. Unfortunately this pump was very expensive, so I came

up with the following alternative:

A new

pool hose, 9 metres long, was purchased and one end adapted to fit the short

hose from the hood, this pool hose is inexpensive and flexible enough to pull

easily behind oneself. The other end of the hose terminated in a box I made up

of scrap wood. This box housed a 3 blade mains powered fan I’d salvaged from

somewhere, the air intake had flyscreen placed across it. The pool hose plugged

into a PVC fitting I got from the plumbing supply store, this was screwed into

the back of the fan box.

Now, the clever bit. I mounted the fan box

against the window to draw in fresh air from outside and blocked the rest of

the window off. When wearing this contraption one gets continually supplied

with clean, cool outside air, great to dry away the sweat produced by a unfit

boat builder! I tied off the pool hose end at my belt to keep it from

separating from the hood hose as I moved about the boat.

On to

the building sequence:

I did

not follow the instructions on the plans there but rather followed a sequence

suitable for my modifications.

The

first item I made for the boat was the rudder blade (the building shed was not

ready yet), this was made from laminated staves of alternating red cedar and

douglas fir, a strip of white ash were the pivot bolt went through and jarrah

hardwood strips for the leading and trailing edge. I used the router method of

shaping the board after making a router guide from computer generated foil

templates. This method produces the very best symmetrical finish and is not particular

difficult to do. My rudder blade has the bottom corners rounded off rather than

the elliptical shape shown on the plan as this was easier to do.

Next

was the centreboard, as this is quite large I bolted a firm 2.4m (8’) long

panel on top of my workbench to make a large flat space for it. As the centre

board is tapered, the routing jig like as used on the rudder blade could not be

used (it only works on parallel sided boards.

I made

another routing jig which shapes the board length wise as against the cross

wise routing of the rudder blade. This worked very well and was easy to do.

On the

CB, because of its large size, the wider and thicker staves used, the

laminating is done on a 6mm thick marine plywood backing, cut to the board

size. Actually, I cut the trailing edge 25mm narrower to later glue on a

hardwood strip to avoid having the finished thin trailing edge of the board in

the plywood.

The

timbers used were jarrah (a local dense hardwood with good marine qualities)

and douglas fir, in alternating staves, all glued to the plywood base. I used

jarrah for the leading, trailing, top and bottom edges and also a piece which

had the recess for the lifting sheaves already cut out.

It is important to clamp the staves firmly to

the table top base as well if they have any slight bend or this bend is later

present in the finished product!

I borrowed some sash clamps and also used my

tube clamps for this job.

When I

tried to move the completed board blank I could barely shift it, it weighed

50kg!

And that was only half the board!

There was no way I could see myself moving

and turning the large, unwieldy finished laminate about to router out the

profile.

Then I

had the inspiration: why not make this centreboard as two halves, a port and

starboard CB so to speak, both in the same case.

In case

this idea did not work it would not be difficult to screw the board halves

together and fair the gap later.

And so it came to pass that my boat sports these

fancy assymetric CB’s and they work very well in the bargain.

Once

the board halves were shaped to the final profile I calculated that the

buoyancy of the submersed volume is about 7kg, in other words, the board would

float, which is something to be expected of a wooden board even if it was

heavy.

I then cut the leading lower corner of each

half board off on the diagonal with my bandsaw and took the off cuts to the

foundry after gluing on a 6mm thick plywood slice to allow for the loss of

material at the saw cut and the expected shrinkage. The foundry cast these

shapes in lead alloyed with a little

antimony to make it tougher. The lead corner pieces were attached with 1/4” ss

allthread pieces, threaded into the lead and inserted into epoxy filled holes

in the board. The gluing face of the lead was first sanded through the wet

epoxy to roughen it and remove the surface oxide layer for a good bond and the

pieces were then epoxied in place to make the boards whole again. The board

halves were then glassed all over with 10oz glass, the final coats saturated

with graphite powder. The rudder blade also was glassed over and received a

graphite coating.

The lead pieces weighed in at 15kg each,

sufficient to make the centre board sink but not too heavy for the lifting

tackle.

Originally

I fitted a 3: 1 purchase for each board half, this needed too much muscle to

raise the board easily so it was later increased to a 5:1 purchase by the

fitting of more sheaves.

I was

not 100% sure if the boards would sink if the lifting rope was let go as the CB

case and pin were a snug, rattle free fit. So I attached a webbing belt to the

leading edges to attach a lowering tackle if required. This was indeed later

used, with a 3:1 purchase, to tug on it a little to start the board moving

down.

There

are plastic flaps over the wide (100mm, 4”) CB slot, to close it off after the

board has exited, this reduces turbulence there to the point where it cannot be

observed from the top of the CB case. These flaps are held with 25x3mm ss

strips, recessed and screwed on each side. It is important that these flaps,

starting at the width of each board forward, overlap aft to each cover

completely across the slot.

If this overlap is too narrow the flap will

curl up and jam the board when raising

it, be warned.

I sourced the plastic strips I used from cold

room strip door material, they work well.

The

next project was the CB case, this had 9mm okoume ply sides, if I did it again

I would use the denser hoop pine ply there for peace of mind. The diagonal

stiffeners were from jarrah, as were the solid cleats along on each side on the

bottom. These cleats need to be shaped to follow the bottom curve. The top of

the case was made in teak, varnished bright with the sloping top section

removable to access the lifting tackle. I also made provision to lock the

boards up for trailering (and take the load off the lifting sheaves) by

inserting a 3/8” ss rod through ss strips inserted into the board tops.

The lifting tackles exit aft under the

outside companion step through deadeyes, then down in the centre of the sloping

cockpit floor to a set of sheaves under the thwart, thence to cleat off at

angled clam cleats fitted on the aft face of the thwart. It is easy to operate

the CB’s from the cockpit.

The CB

pivot pin was initially 1/2” ss but I had to increase this to a 5/8” ss rod as

the smaller diameter rod actually bent

slightly (this may have happened after the board kicked up while once

passing too close over a reef, thanks for pivoting boards!)

With

the CB, its case and the rudder blade out of the way, the boatshed finished,

the boat building could proceed in earnest. First, all plywood sheets received

a soaking coat of epoxy, thinned with TPRDA, then another coat which was sanded

with a random orbital sander.

This job is easiest done while the whole

building floor is available to set up tables and trestles and do a number of

sheets at a time. Its really the easiest way to totally cover all the plywood

with epoxy, the pre coated sheets also give a cleaner cut from the jigsaw

(sabre saw) with less splintering on the cutting line.

The

bulkheads came next, I tried to pre finish them as much as possible (there are

no epoxy runs on a horizontal surface)

and fit all the cleats for the furniture. In retrospect I should have fitted

only the cleats to one side, opposite of where the supports from the building

frame go, as some of the cleats got in the way there later.

For

cleats I used a triangular cross section of western red cedar, made by ripping

(25x25mm, 1”x1”) stock diagonally. They are just as strong but half the weight

than square ones and you get twice as many out of a length of wood. They are

also easy to plane and sand to any required bevel.

I bought a heap of leftover cedar from a

house builder cheaply, these were varying length planks and they had heaps of

knots. After ripping them to size, there were lots of useful lengths between

the knots as most cleats used in the boat were shortish anyway.

I must have used hundreds of metres of

cleats, its amazing how they disappear into the construction.

Clamping these triangular pieces was no

problem, I made a dozen short pieces of wood with a matching cut out to fit

over the angular edge when applying the clamps.

Since I

had so much cleating material I fitted these on both sides of all joins, making

for a very strong construction. I used no epoxy fillets anywhere inside my

boat, all was done with these triangular cleats.

About

gluing bits onto bulkheads and gluing generally, often it is not possible to use

clamps as they cannot reach the desired spot. I used lead weights, made from

200mm lengths of 25x50mm RHS

(rectangular hollow steel) filled with lead, about eight of these. Also smaller

ones of 20x20mm RHS, a dozen of these. Then there were lead ingots made by

casting lead into a 300mm long section of steel channel, 50x100mm, with welded

up ends. These weighed 15kg each, I had six of these. All these weights came in very handy.

The

ballast weight slabs were also home poured into a steel channel, I made those

to be of 50kg weight as I could not handle anything heavier by myself. The

ballast bolts were cast in, these I made from 1/2” ss allthread sections with a

T crossbar welded on. The lead pouring is a story by itself, not difficult but

can it be dangerous, send me an email if you want the details.

The

blkhd A was made from 2 layers of 6mm hoop pine ply, this way it was easy to

make a lip for the centre opening cover. This cover was made from the cut outs

by carefully cutting with a jig saw and using a row of small holes for the

start of the cut.

The

transom was also laminated from 2 layers of 6mm okoume ply to get the desired

curve at its top edge, it also had the laminated top beam and curved aft face

of the motor well fitted on already.

At this

stage it is also advisable to consider just where the wiring and plumbing runs

past the bulkheads and drill the appropriate holes into them as these might be

difficult to drill later. I used the outboard side of the carlins to run my

wiring, a white 25x25mm ducting with snap on lid is screwed on there, making

the wiring invisible from the cabin yet for it to be accessible and reach

everywhere. To this end there were 20mm holes drilled through the blkhds,

outboard of the carlin notches, easy to do at this stage but very difficult

later in the building process. I had to elongate some of these holes later with

a file as there were more wires than I thought to go through them!

Now it

was time to assembly the building frame. I strung a length of piano wire, through

notches at the bottom of the building frame cross members, along the centre

line. This wire was carefully levelled and tension applied by means of eye

bolts at each end to have no sag along its length. This was the reference line

against which everything was lined up.

The building frame, made of heavy 150x50 timber was also bolted to the concrete

floor to make it unmovable.

I

installed the blkhds at their marked

locations on the building frame, (take care from which side of them you measure this!), using the method described

in Kirby’s plans.

If I did this again I would also cross brace the blkhds from

the roof rafters, making a much more secure 3 point fixing. The blkhds, on

their two temporary legs, are quite wobbly and want to move about when the chine

logs are bent around later. You may also have to temporary clamp or screw

stiffener logs across the blkhd openings to avoid distortion on some of them

during this process.

Once

the bklhds were located in position and all measurements crosschecked about 3

times, the chine and sheer logs can be fitted. The dimensions specified for

these makes it very difficult to

bend these around in one piece, laminating as suggested by cutting into inner

and outer half also is troublesome because they have to bend both ways. I made

mine up by laminating them from upper and lower halves, these, being almost

square, bend easily in both directions. I also got less waste this way as I cut

these strips from planks of kauri pine.

These

planks were only 3.6m (12’) long so 3 strip

sections were scarved end to end to make up the full length. The lengths

were later installed offset to place the scarf joins at a different place on

the complete laminate. Make sure these pieces overhang the hull by about 0.5m

(2’) aft and 0.25m(1’) forward to make a fair curve and you got something to

pull against. I scarfed up all the pieces required for the 4 chine log and 4 sheer clamp lengths at

once, using the jig described earlier. These were stored on a shelf until

needed.

When

cutting the notches in the blkhds for these logs it pays to cut them smaller

than shown on the plan initially as some have a far bit of a bevel. You also

need to allow for the topside bevels when gluing on the bulkhead doublers here.

Use one of the scarfed lengths as a batten to bend around the notches and mark

the bevels. Once these have been adjusted glue some extra large cleats on

either side of the blkhd notches which do not have doublers there to accept the

screws holding the chine and sheer logs until the epoxy cures, these of course

also need to be bevelled. The blkhd itself is too thin there to hold screws.

Then I

installed the temporary fore and aft blkhd which holds the stem in its place.

The precise location of where the laminated logs meet the stem were marked on

this blkhd. The stem for my boat was laminated from douglas fir and white ash

and screwed to the temporary fore and aft blkhd with small brackets.

Now came the tricky job of marking and

cutting the notches for the chine logs and sheer clamps into the stem, I did

this a little bit at a time, using the scarfed length batten to get the bevels

right, it was not an easy job as everything comes to a point here. The forward

ends of the chine log and sheer clamp were tapered too as the stem is not fat enough

to accept their full thickness. I also fitted a stout, laminated, knee to the

chine log / stem joint as this area looked a bit weak to me.

Take your time and work with care, this joint

takes the brunt of any collision with floating hazards!

To install

the chine logs, choose one side and

dryfit and screw the log in place to the notch corners of the bulkheads,

starting in the middle and working fore and aft until you are satisfied all

fits in place and runs a fair curve. Stand back and sight along the entire boat

to make sure!

Mark the glue lines with pencil on the blkhds

and logs. Disassemble and coat with epoxy all the log surfaces facing the

inside the boat, leaving the marked gluing places dry. I chamfered the inner

corners of these logs for a pleasing look using a power plane. The chamfer just

runs out before each of the blkhds. Do this also for the other side. When you

have done this you can start gluing

these logs in place. It’s a bit tricky to handle these long snaking bits of

wood without smearing epoxy everywhere but can be done if some temporary

supports are clamped to the blkhds. Start at Blkhd E and work both ways,

driving the screws back into the holes from the dry fitting stage. Then do the

opposite side of the boat with your next log to avoid distortion of the blkhds.

When

all of the chine log and sheer clamp halves have been glued in place in this

manner you may remove the screws or simply leave them there if they were countersink

stainless screws. Clean out the squeezed out epoxy from the remaining notch

areas and dry install the other halves of the laminate as before. You can now

use clamps to clamp them to the existing log halves as well to follow the exact

same curve, mark and pre coat inside surfaces as before. Then you need to glue

the entire length of the mating surfaces and the notches all at once, use the

screws as well as clamps to hold everything in place until all is cured. This

operation is a bit tricky to do but if thought it out well there should be no

problem. I used about 20 clamps for this process, if you don’t have that many

borrow some before you mix the epoxy L.

Here I should pass on another trick which

made cleaning up epoxy squeeze out much easier. Initially I used a chisel

to scrape off the excess but this had to be done after a certain curing time

while the epoxy was still soft which often coincided with my sleeping time.

Someone on the rec.boats.building newsgroup mentioned a heat gun to soften the

epoxy and scrape it off, it works like a charm!

You

need an electric heat gun with a rather small nozzle (1/4” diameter approx.) I

use a Leister heat gun, but others also will do as long they have a heat

control to limit the nozzle temperature to less than 200 degrees Celsius. You

can always drill some bleed holes into the nozzle if it is too hot, the epoxy

surface must not char if the nozzle is held stationary for a few seconds.

I also found a blunt chisel useful there, just heat the epoxy bead with the nozzle

and follow with the chisel to lift the softened excess epoxy off without

cutting into the wood. At corners I used a gauge to get a small radius finish

like a tiny fillet. There is almost no sanding required with this process and

consequently no dust.

The

next job will be to install the CB trunk, it’s a big, unwieldy, thing and I

rigged some tackles from the ceiling to suspend and lower it in place. Another

reason why you need a high ceiling in your building shed.

Dry fit everything and mark where the epoxy

glue goes. The first bottom layer of ply butts against the trunk sides in my

boat so the trunk stood proud of the bulkheads by 12mm at this stage. The

tackles were used to raise the thing

for application of the epoxy then it was lowered and clamped in place where

clamping was possible. Place spreader pieces into the CB slot to avoid it being

squashed inward and have consequently a difficult fit of the CB later.

Now the

hull has taken on a shape resembling the boat, I then decided to fit as much of

the interior fittings while the sides and the bottom were still off for easy

access.

This

comprised of all the vertical panels, such as bunk fronts, cockpit sides and

floor stiffener etc. These were first dry fitted to their appropriate cleats

and marked, then I applied the final epoxy coat on the bench and two coats of

white primer before gluing them in place.

A note

about painting the interior: it was very apparent from the nearly finished hull

I had seen before I started on mine that it would be difficult, messy and in

some places impossible to paint some areas inside of the boat if these were

left until the hull was complete.

So I

applied two coats of white undercoat paint to

all interior surfaces on top

of the epoxy coats which were not left bright and varnished later, prior to

gluing them in place. There the later inaccessible or difficult to get to

surfaces received a final coat of white gloss paint (I used interior marine

paint).

My

reason for painting in addition to the epoxy coat is: it is much easier to spot

holidays (missed parts) in the white paint cover than in the epoxy coating, any

such places got additional covering and the light colour makes it much easier

to see small things in lockers and such. And I don’t have to worry about condensation

encouraging wood rot at some hidden away place.

It may

look like slowing up the building process when painting everything before

installing it into the hull but it sure is much easier to do at this stage.

The

cockpit floor has a vertical fore and aft stiffening panel under its centre,

running from the aft face of the CB case to blkhd G and another one between

blkhd G and H. These panels had large circles cut out to lighten them and allow

the ventilation of the buoyancy chambers if their ports are opened. I think

this modification is essential to bear the weight of the crew standing in the

cockpit.

On the

aft face of blkhd C and forward face of blkhd F I fitted ss chainplates under the side deck area. These were

screwed to the Blkhd stiffeners and to the blkhd to spread the load, they had

holes on top to install a 3/8” ss U-bolt which fitted through a hardwood cleat

.

The

purpose of these U-bolts was to attach the slings used for turning the boat

over. I reinstalled these U-bolts later permanently after the side decks were

fitted and they provide now an easy way to hook up to the lifting gear under

the shed roof to lift the boat onto its trailer.

The

anchor locker needs to be done at this stage if it is desired to build one in.

For this I built up the side faces of

the stem with western red cedar strips to fill the wedge shaped gap which would

be there after the topsides are fitted. I made small notches halfway along the

aft face of the stem from where 25x25mm cedar strips angled up to the outside

face of blkhd A at the sheer clamp. This was the support for the sloping locker

bottom. The reason the angled supports were of cedar is they need to be shaped

later to be flush against the topsides, use a batten to get this shaping right.

When

the boat is rightway up the sloping locker floor has its lowest point just

under the towing U-bolt in the stem and it slopes up aft to facilitate draining

of the locker.

As the

locker sides are the boats topsides it only remained to fit the locker back

which was up to the foredeck level just forward of the deck doubler here. Make

sure the mast tube has room aft of the anchor locker back!

The entire anchor locker was glassed with

10oz glass cloth to avoid damage by sharp anchor flukes later.

It is advantageous

to have this tube is available at this stage to install the bottom supports for

the mast tube. These would be much more difficult to fit later through the

opening in blkhd A if the topsides block side access.

If you

follow my philosophy of painting all inside surfaces don’t forget the forward

face of blkhd A, very difficult to paint here later.

Once

all vertical inside panels had been installed, painted and faired to the bottom

curve, the first layer of the bottom was fitted.

As mentioned earlier, these panels were

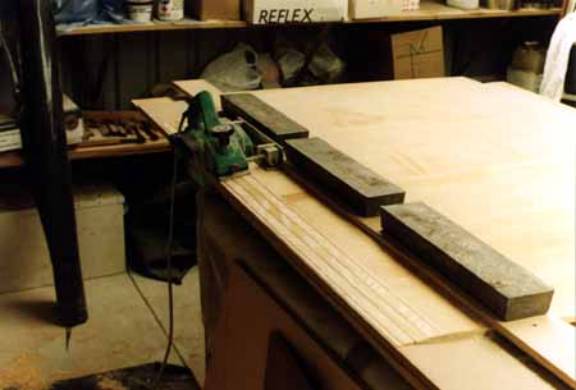

scarfed in place. To scarf the plywood edges I made a scarfing fence attachment

for my Hitachi power planer. The planer already had one transverse hole to hold

a fence, I made another hole on the other end of the planer to hold a fence

attached by two points which could not flex sideways. This fence is a length of

aluminium angle, 50x50x3mm and as long as the planer. The angle was located

with the horizontal side level to the planer bottom and the vertical side

facing away from the planer. The two rods to the fixing holes in the planer

body were attached at the fence by a fitting screwed to the aluminium angle which allowed to tilt and

lock this angle in place in relation to the planer bottom. By setting the angle

on a slight tilt (found by experiment how much) and running this angle against

a guide clamped to the plywood sheet, the planer , being held at an angle, took

a tapering bite into the ply. Repeated passes produced a perfect scarf join. Of

course this could also be done by using a hand plane but the power plane is

quicker and it allows the job to be done on the floor if the plywood sheet is supported by another one.

I

placed the first layer of the bottom with the sheets grain running fore and

aft. The middle of the hull is wider than the sheets but the CB case splits

most of this area in half anyway. On my boat all the first layer scarf joins

were located over a blkhd so that no joins were visible from the inside on my

bright finished cabin floor. This requires carefully juggling to avoid wastage.

The sheet forward of blkhd D is still too narrow to reach to the boat sides so

I scarfer triangular off cuts on there. These joins are under the battrey

lockers.

I used

8 sheets of 4x8’ marine ply for both layers, 12mm marine ply is expensive,

measure twice and cut once J.

The

panels were first installed dry with screws to the blkhds and chine logs and

weights on top and then all gluing areas marked off from inside, then glued on, one sheet at a time. It is

difficult to move these heavy sheets in place once the epoxy is applied, they

will slide off quicker than you can reach for the battery drill to drive the

screws home. I inserted some temporary eye bolts to suspend the sheet over the

desired location from the roof. Applying epoxy to the bulkheads and to the

underside of the hanging sheet was manageable, the sheet was then lowered in

place and screwed home.

If you

use the scarfing method of joining you need to start at the sheets on each side

of the CB trunk, the forward and aft scarfes on the same side, facing away from

each other. The feather edge of the scarf is always down, against the blkhd.

Then

work forward and aft alternately with the sheets scarfed on opposite sides,

take care to work out which side is scarfed as its very easy to get confused

here. Mark all scarf sides while

marking out the sheet outline cuts, then check them again before you

fire up the planer.

The

epoxy squeezed out along the scarf line on the blkhd needs to be carefully

cleaned up by the heat gun method to ensure the next sheet fits perfectly. Once

you have done the first scarf join the rest just become routine, its really not

difficult to join large panel segments this way.

I made

good use of the heavy lead ingots along the scarf gluing line to make sure it

fits without voids, its better to have a very slight hollow than a bump there

which would need to be belt sanded off later.

Once

all the first layer bottom panels were fitted I used the belt sander to trim

the plywood edge along the chine log to its bevel.

The

topside panels were next on the list, these were scarfed and fitted, one at a

time, as the bottom panels. Here it would have been too much wastage of plywood

to try to get all the scarf joins located over a blkhd. I started from aft and

the first join did coincide with a blkhd. The next one fell just short of blkhd

C. A stout , plastic covered, plank was screwed to the already fitted panel

inside at the scarf join to provide a

pressure area for the next panel on the feather edge. As usual, everything was

fitted dry first to drill the screw holes which held the panel to the chine

log. Another plastic covered plank on the outside sandwiched the scarf join and

these were screwed together to keep pressure on the scarf while the epoxy set.

In this

way all the topside panels were installed, now the hull really looked good.

The

chines were belt sanded to match the bottom plywood and the second layer of the

bottom followed, overlapping the topside edges.

This I installed with the plywood panel grain

lying across the hull, starting aft and working to the bow one panel at a time

was marked, cut out and fitted. The suspension method was again used to apply

the epoxy. There must be some screws, located and threaded partway, to lock the

panels and prevent their sliding off. The epoxy was spread with a notched

applicator with the bead directions at right angles on the hull and the

suspended panel. The sawhorses were handy there to make a plank walkway along

the hull to easily reach this area.

I also

used the extra heavy ballast slabs to press down the laminate, with the first

layer installed, the hull could take this extra weight. These panels did not

overlap the edges of the CB slot side panels as I later glued a hardwood strip

in place there to bury the edge grain of the plywood in this wear area.

The

hull was marked now with its waterline. To do this I drilled small holes at the

blkhd locations, on which the waterline had been marked previously, through the

topsides. Nails were pushed into these holes from the outside and a long batten

bent around this and the waterline marked onto the hull sides.

When

the double layer bottom was complete the chine edges were rounded off well but

the transom edge left square (makes less turbulence there).

Fill all

screw holes and check the entire hull surface for epoxy drips and lumps which

need to be removed before the glassing stage.

I

glassed the bottom with 10oz woven glass cloth. First the glass cloth was cut

and placed on the dry hull, it was smoothed and the ends fixed with short

pieces of masking tape. Then the epoxy was applied, pouring it from the mixing

container onto the glass and spread carefully with a plastic spreader until the

glass was roughly covered. Then I used a foam roller to toll it into the weave.

Try to apply not too much epoxy, just enough to fill the weave and so that the

white glass becomes transparent.

Next

came the topsides, one at a time. Spread the epoxy as above, making sure the

glass cloth does not slide about. It may be required to insert strategic

staples to stop the wetted out glass sliding off. Remove the staples when the

epoxy has cured.

On my

boat the outside ballast was attached now. There is a double layer of lead

slabs on each side, the lower layer had holes cast in where the bolts cast into

the upper layer passed through.

The lead slabs were placed in location and

the outline marked on the hull. A whack with a rawhide mallet easily formed the

lead to the bottom curve of the hull. As mentioned earlier, I kept the slab weight

to 50kg, this required 12 slabs for the ballast.

I since

removed the upper aftermost slab later so there are now only 10 lead slabs on

the outside of the hull bottom.

Flipping

the first layer over and aside, the marked area was sanded with 40 grit as was

the lead surface and butting area. The lead was covered with straight epoxy

which was sanded in wet and the hull also wetted out. Next a generous buttering

of fortified epoxy to both surfaces and the slabs were flipped back into

position. To move the heavy, epoxy coated, lead slabs it is advisable to devise

some kind of handles to grip the slabs. Some temporary nails kept the slabs

from sliding off until the epoxy cured.

Then

the holes for the bolts were drilled into the hull through the cast in holes in

the lower slab layer and the process repeated to epoxy on the top layer. Make

sure that there is a washer and nut placed on the bolts inside the hull to stop

the epoxy running out down there.

Faired

pieces of hardwood were epoxied ahead and aft of the lead ballast and any gaps

were filled and smoothed out.

Then I

glassed a very heavy weight triaxial glass tape, 150mm wide, around the chines

for the full length, the centre of the

hull bottom from the bow to the CB slot and over the faired lead ballast

skegs.

This

was for extra wear protection when the boat is on the trailer or while being

beached.

The

recess for the CB slot flaps was also routed out at this stage, making sure

this area received a very good, soak in, epoxy covering after. The opening for

the motor leg was cut out next and its lid finished.

With

the entire hull now glassed and after washing any amine blush thoroughly off

with water, the hull bottom up to the waterline was covered with an epoxy and

graphite powder mixture. Subsequent coats also had fairing compound added. This

was smoothed and faired with longboards as described below.

On the

topsides I rolled on another coat of epoxy to fill the weave. Then if there any

hollows or bumps they need to be filled with epoxy, thickened by filling

compound. Spread this with a notched applicator in a vertical direction. Do the

same to the hull bottom but also mix in graphite powder to keep the mixture

black. Make sure the ballast skegs and triaxial tape edges are faired in well

with this mixture.

Now the

longboarding. Begin sanding in a fore

and aft direction across the beads

until the sanding starts cutting into the plain epoxy coat, do not sand into

the glass layer.

This is

a very messy job, keep that vacuum cleaner busy and don’t forget the dust mask.

I wore disposable Tyvek overalls, they

lasted for a few sessions and are quite cheap.

Next

all the remaining grooves between the epoxy beads on the hull need to be filled

with epoxy fairing compound, applied with a straight edge applicator. Another

light sanding and she should be ready for undercoating. I made the mistake to

think that very slight dimples would be filled by the undercoat, this took too

many coats and lots of sanding. Better to get the hull as smooth as possible

with the epoxy and filling compound first!

With

the hull sides faired and undercoated, the bottom smooth with graphite filled

epoxy, the hull was now ready for the big moment of turning over.

Before

I did this I placed two stout 100x100mm logs along the ballast skegs and

levelled them carefully. Then I measured and glued on spacers to the logs to

follow the skeg curvature. After cross braces were fitted and the logs exact

position marked on the lead skegs with masking tape, they were removed and put

aside for now. These were used later for the hull to sit on and remain level

when she was turned over.

Two

lifting webbing straps from the winch contraption overhead were attached on one

side of the hull to the U-bolts fitted to the chainplates. The other two

straps, on the opposite side, were lashed to the U-bolts there and continued

under the hull to shackle to the U-bolts where the first straps terminated.

To

operate this, both winches (one at each side of the hull) were wound in to take

the weight of the hull. Wrap padding anywhere the webbing straps cross anything

sharp. Then all the supports to the building frame need to be removed to free

the hull.

IF YOU

USE THIS SYSTEM MAKE SURE YOUR LIFTING GEAR AND THE ROOF BEAMS ARE UP TO THE

TASK!

I

blocked the hull up with temporary logs across the building frame for extra

safety while I crawled under there to undo and remove all the blkhd supports.

When

all was clear the building frame too was dismantled and removed, keeping the

safety logs in place.

All the

lifting gear was double checked and the hull lifted off the logs a little by

each winch. I let it hang there over night to make sure all was OK to take the

weight!

Now,

one winch, on the side where the webbing was lashed to the U-bolts was used to

raise the hull a little. At the same time the winch on the other side of the

hull lowered it a little.

This

was continued, gradually turning the hull over while it was never more than a

few inches above the floor.

When

the hull was at 90 degrees the lashing mentioned earlier was removed, the hull

still being cradled and supported by the webbing attached to the other U-bolt.

All the weight of the ballast was now borne by the lowering winch and it

groaned accordingly.

THE

WINCH AND TACKLE MUST BE RATED FOR THE FULL WEIGHT OF THE HULL AND BALLAST, an

estimated 1200 kg at this stage in my case.

Both

winches were later used on the boat trailer, one for tilting it, the other to

retrieve the boat.

The

turning over continued in this fashion until she was rightway up. The hull was

raised a little to allow the prepared levelling logs to slide under the skegs

and lowered to rest there. There was no drama with this method of hull turning

over other than the alarming groaning noises from the winch (which I forgot to

grease).

The

hull was checked if it was level and secure (no rocking!) and the beer was

opened.

The

webbing spools for the lifting contraption under the roof were spaced to fit

the hull width so no crushing of the blkhds occurred, I temporarily reinforced

blkhd F with cross beams for extra security.

Now the fitout could begin in earnest, I

started with the Cockpit floor to have something to stand on while climbing

about the hull. Temporary planks made a step where the cockpit seats were.

As

before, all items were dry fitted, then removed and finished on their under /

insides to the final paint cover before epoxying them into place.

I

figured it would take me one year to finish the boat from there, it took nearly

two years in the end. Its tempting to cut corners and hurry on for the

launching while the inside of the boat is not finished. I believe in getting

this job done completely to enjoy the sailing later without seeing lots of

things which still need to be finished off in the boat all the time.

With the

cockpit seats and their locker lids done, the thwart installed, all the bunk

tops and their locker lids finished, the motor bracket operational and the tank shelf installed

there I tackled the inside shelfs.

For all

items abutting the hull sides I first glued those triangular cleats in place,

bevelled to the correct angle. Then I got a piece of scrap ply such as old door

skin or stiff cardboard and cut it roughly to shape. Then, holding this in

place against the hull side, I used one of the perspex disks, a pencil through

the hole in the centre and the disk rolling along the hull side while it was

kept flat against the scrap ply transferred the hull curve to the scrap ply.

After trimming this and checking for a good fit this shape was then transferred

onto the okoume plywood. In my boat most of the furniture is symmetrical on

both sides so I often could flip over the template and use it for the other

side.

In case

you are wondering how I clamped the triangular cleats to the hull while the

epoxy set, I used long battens to jam them in place from the opposite hull /

locker sides for this. Just remember this when you later crawl out of there and

don’t knock the battens off as I often did L.

When

all inside fittings were in place and I no longer needed to pass large items

into the boat the cabin sides and coaming were fitted. Do not cut out the windows first as the sides would then not bend fair

to the blkhds. These panels were also scarfed in situ, easier than trying to

get the long curved shape right in one piece. The cockpit roof was laminated

next, out of two layers of 4mm okoume plywood.

The

orientation and scarfing of the roof sections was done in similar fashion as on

the hull bottom with the difference that the entire inner layer was first

scarfed together on the floor and installed as one piece. The second layer was

vacuum bagged on. I’ll provide the details of this process to those who are

wishing to do it that way.

With

the cabin roof finished only the side decks remained off the boat, these were

deliberately left off until last as it was easier to install all the wiring now

into ducts screwed to the outside of the carlins. The centre cabin light had

its wiring run into a groove routed in the roof beam before installing the

cabin roof. The distribution panel and switch panel are in the small cubbies in

the forward face of blkhd E, the wiring to this goes up from the carlin duct

through the forward coaming void into the upper cubby space.

The

only place I could find to run the wiring out of sight from stbd to port was through a conduit that

passes under the outside companion step (this step is as deep as the angled add

on blkhd).

I also fitted a second conduit there to run

the water hose from the stbd tank to the pump on the port side. The water hoses

were run up under a ply cover aft of the blkhd E stiffener. The deck filler is

just above in the side deck.

All

this work needs to be considered while the boat still is in the skeleton stage,

once you have covered up here its very difficult to cut the required openings.

Before

fitting the side decks, which were scarfed in place as usual with the scarfes

at blkhd locations, I glued on an outed sheer clamp as an afterthought . This

was made from scarfed lengths of douglas fir, about 20x50mm, and clamped to the

inner sheer clamp while the glue set. After this was sanded to follow the sheer

line the side decks were installed.

Then

I used a power plane to shave off the angled outer side of this outer sheer

clamp to make it vertical. A vertical surface is much tougher than an angled

one for the inevitable bumps when coming alongside. Removable teak rub rails,

which were scarfed up from 4 sections, was screwed to this. The rub rail

continues across the transom for visual effects.

Then

I used a power plane to shave off the angled outer side of this outer sheer

clamp to make it vertical. A vertical surface is much tougher than an angled

one for the inevitable bumps when coming alongside. Removable teak rub rails,

which were scarfed up from 4 sections, was screwed to this. The rub rail

continues across the transom for visual effects.

The

boats maximum beam was increased by this addition to 2.5m, the legal maximum

towing width here. It also gives a slightly wider side deck to fit the last

item there, a trapezoid shape toe rail. This is in 4 sections, each terminating

at the stanchion bases to prevent water pooling there.

Now the

hull was pretty much finished apart from some teak trim here and there and the

painting.

I spent

ages on filling and sanding with high build primer and it was really worth the

effort, most people seeing the boat were thinking she was built of fibreglass.

The

final finish is only as good as the surface beneath it and any hollows are

magnified by the gloss paint.

Using

two part paint would give a tougher finish but these paints really need a

professional with a spray gun. My boat

looks pretty good with the one pot polyurethane paint, its also easier

to touch up scratches on this finish later.

I

painted the cabin top with an off white colour in the slightly stippled finish produced

by the foam roller. This hid rather than highlight the small imperfections

there, fairing the highly chambered surface was much more tricky than the hull

was.

I

painted the cabin top with an off white colour in the slightly stippled finish produced

by the foam roller. This hid rather than highlight the small imperfections

there, fairing the highly chambered surface was much more tricky than the hull

was.

The

side decks were coated with non slip paint of light grey colour, the masking

around the fittings is a bit tedious. Rather than trying to curve masking tape

around the small radius at the deck fittings I used the clear film as used for

book covers and such. The shapes were cut with scissors and the film stuck to

the appropriate place, it proved successful and no paint seeped under its

edges.

There

are some bright finished teak trims on the outside of my boat, I kept those to

a minimum to keep the varnishing maintenance low. The teak slats on the seat

and cockpit floor were left as is and

they wear to a pleasing grey finish.

Initially

I planned to just paint the cockpit and had covered all areas with glass cloth

but this finish looked a bit too plain and slippery there, hence the addition

of the slats for a touch of class.

When

bolting items to the cockpit or deck I always drilled the hole one size up and

coated it with epoxy along its length to waterproof the wood. The item then was

also bedded with sikaflex and I expect no leaks on my boat (so far so good).

The

boat was now nearly finished, I fitted the motor which had to be lowered onto

the bracket tracks by a chain hoist, it’s a tight fit in there.

The

hull was the raised as high as the lifting gear allowed, some sturdy steel

trestles placed under the lead skegs for safety, and the centreboards were

installed. They were lifted into place by their own tackles, I made large,

thin, teflon disks to fit on each side and it was a tricky operation to raise

the boards into the CB case while keeping the teflon disks lined up.

All

that remained was to roll the trailer under her and lower the boat. The home

made trailer looked a lot better than it functioned in its original design, two

major modifications later this problem was finally solved. I now can launch and

retrieve the boat single handed as well as sailing her that way.

She

turned out great, much better than I had hoped at the beginning.

Keep in

mind that I wrote the above from memory after the boat had been finished and

launched for 10 months. If you find something confusing please contact me and I

may be able to explain it better.

Have

fun building your boat.

-Klaus-